Introduction

Within This Page

A new model of laboratory design is emerging, one that creates lab environments that are responsive to present needs and capable of accommodating future demands. Several key needs are driving the development of this model:

- The need to create "social buildings" that foster interaction and team-based research;

- The need to achieve an appropriate balance between "open" and "closed" labs;

- The need for flexibility to accommodate change;

- The need to design for technology to provide access to electronic communications systems throughout the building, which has immense implications on lab design;

- The need for environmental sustainability; and

- The need, in some cases, to develop science parks to facilitate partnerships between government, private-sector industry, and academia.

Description

A. "Social Buildings" For Team-Based Research

Modern science is an intensely social activity. The most productive and successful scientists are intimately familiar with both the substance and style of each other's work. They display an astonishing capacity to adopt new research approaches and tools as quickly as they become available. Thus, science functions best when it is supported by architecture that facilitates both structured and informal interaction, flexible use of space, and sharing of resources.

See also, WBDG Productive; Productive—Design for the Changing Workplace; Psychosocial Value of Space.

Meeting Places

A critical consideration in designing such an environment is to establish places—break rooms, meeting rooms, atrium spaces—where people can congregate outside their labs to talk with one another. Even stairways, fire stairs, or stairs off an atrium with built-in window seats can provide opportunities for people to meet and exchange ideas. Designers must look for opportunities for such uses in public spaces, making optimal use of every square foot of the building.

Atrium spaces are usually very active, popular spaces that support better communication.

Team-Based Labs

Laboratories should have casework and engineering services that can easily be changed to support each research team. The CDC building 110 project was designed with generic architectural and engineering services. At move in, the research teams were able to create over 60 different custom laboratory configurations.

Collaborative research requires teams of scientists with varying expertise to form interdisciplinary research units. As networks connect people and organizations, sharing data within a team and with other research teams becomes less complicated. So, designers are organizing space in new ways. Laboratory designers can support collaborative research by:

- Creating flexible engineering systems and casework that encourage research teams to alter their spaces to meet their needs

- Designing offices and write-up areas as places where people can work in teams

- Creating "research centers" that are team-based

- Creating all the space necessary for research team members to operate properly near each other

- Minimizing or eliminating spaces that are identified with a particular department

- Establishing clearly defined circulation patterns

- Provide interior glazing to allow people to see one another.

B. "Open" Versus "Closed" Labs

An increasing number of research institutions are creating "open" labs to support team-based work. The open lab concept is significantly different from that of the "closed" lab of the past, which was based on accommodating the individual principle investigator. In open labs, researchers share not only the space itself but also equipment, bench space, and support staff. The open lab format facilitates communication between scientists and makes the lab more easily adaptable for future needs. A wide variety of labs—from wet biology and chemistry labs, to engineering labs, to dry computer science facilities—are now being designed as open labs. Most laboratory facilities built or designed since the mid-1990s in the U.S. possess some type of open lab.

For the Phase 2 Neuroscience facility at NIH the open labs are designed with the offices to the right and direct access to the labs and the lab support to the left. The open labs are the focal point.

There can be two or more open labs on a floor, encouraging multiple teams to focus on separate research projects. The architectural and engineering systems should be designed to affordably accommodate multiple floor plans that can easily be changed according to the research teams' needs.

Closed labs are still needed for specific kinds of research or for certain equipment. Nuclear magnetic resonance (NMR) equipment, electron microscopes, tissue culture labs, darkrooms, and glass washing are examples of equipment and activities that must be housed in separate, dedicated spaces.

Moreover, some researchers find it difficult or unacceptable to work in a lab that is open to everyone. They may need some dedicated space for specific research in an individual closed lab. In some cases, individual closed labs can directly access a larger, shared open lab. When a researcher requires a separate space, an individual closed lab can meet his or her needs; when it is necessary and beneficial to work as a team, the main open lab is used. Equipment and bench space can be shared in the large open lab, thereby helping to reduce the cost of research. This concept can be taken further to create a lab module that allows glass walls to be located almost anywhere. The glass walls allow people to see each other, while also having their individual spaces.

C. Flexibility

Maximizing flexibility has always been a key concern in designing or renovating a laboratory building. Flexibility can mean several things, including the ability to expand easily, to readily accommodate reconfigurations and other changes, and to permit a variety of uses.

See also, WBDG Productive and Productive—Design for the Changing Nature of Work; Productive—Integrate Technological Tools; Productive—Assure Reliable Systems and Spaces

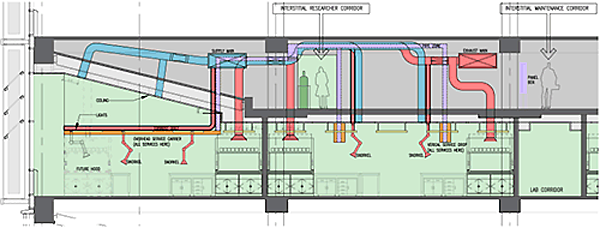

Flexible Engineering Systems

Flexible engineering services—supply and exhaust air, water, electricity, voice/data, vacuum systems—are extremely important to most labs. Labs must have easy connects/disconnects at the walls and ceiling to allow for fast, affordable hookups of equipment. The engineering systems may need to be designed to enable fume hoods to be removed or added, to allow the space to be changed from a lab environment to an office and then back again, or to allow maintenance of the controls outside the lab.

At NC State, these engineering laboratories are supported by highly flexible mechanical systems that allow for equipment setups to be completed in almost endless number of scenarios. Change is encouraged and seen as beneficial in most cases.

From the start, mechanical systems need to be designed for a maximum number of fume hoods in the building. Ductwork can be sized to allow for change and growth and vertical exhaust risers provided for future fume hoods in the initial construction. When a hood is required, the duct can simply be run from the hood to the installed vertical riser. The mechanical systems will need to be re-balanced when a fume hood is added or deleted to efficiently accommodate the numbers of hoods in use and the air changes necessary through each room. Vertical risers are primarily used for the hoods that exhaust special chemicals (such as radioactive and perchloric fumes) that cannot be mixed into the main laboratory exhaust system. Installing vertical risers during initial construction takes little time and costs approximately one-third of what it costs for retrofitting to add vertical risers later on.

Engineering systems should be designed to service initial demands and at least an additional 25% for anticipated future programs. Space should be allowed in utility corridors, ceilings, and vertical chases for future heating, ventilation, and air conditioning (HVAC), plumbing, and electrical needs. Service shutoff valves should be easily accessible, located in a box in the wall at the entry to the lab or in the ceiling at the entry. All pipes, valves, and clean-outs should be clearly labeled to identify the contents, pressure, and temperature.

See also WBDG High Performance HVAC.

Equipment Zones

It typically takes about three years for a 10,000 square meter lab building to be designed and built. During this time an organization's research needs may change or the people doing the research may leave and be replaced by others. In either case, there is a good chance that the purpose of the lab will change. If the entire lab is fitted with new casework, the casework may have to be changed before anyone occupies the new laboratory.

It is recommended to allocate approximately 25% of the space in most labs for equipment zones. This provides space for the researchers to come in and move casework and equipment around as well as add casework and/or equipment where necessary. The equipment zone shown in the dark rectangular color in this photo becomes a type of swing space.

Equipment zones are usually fitted out when the research team moves into the lab—that is, when the team knows exactly what will be needed to do the work. The creation of equipment zones that accommodate change easily is a cost-effective design opportunity. The lab can be generic, with 50%–70% casework initially and the rest of the lab fitted out later. The casework is usually located on the outside wall, with islands defined as equipment zones. It may also be helpful to locate 3 ft. to 6 ft. equipment zones on the outside walls to accommodate cylinders near fume hoods and refrigerators at the perimeter.

Generic Labs

When a laboratory facility is designed generically, all the labs are the same size and are outfitted with the same basic engineering services and casework. Generic labs are a sensible option when it is not known who will occupy the space or what specific type of research will be conducted there. Generic lab design may also make sense from an administrative standpoint, since each team or researcher is given the same basic amenities. The best generic labs have some flexibility built in and can be readily modified for the installation of equipment or for changes to the engineering services or casework. Many new labs are designed with mobile casework everywhere except for the fixed fume hoods and sinks.

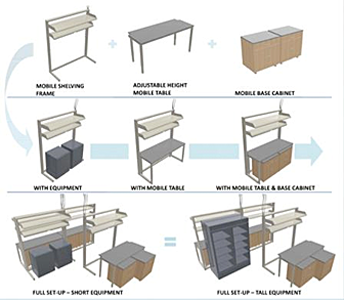

Mobile Casework

Technological advances allow for more research procedures to be automated. In the past equipment was often squeezed into an existing lab setup; today's labs must be designed to accept the needed equipment easily. There are several types of movable casework to consider. Storage cabinets that are 7 ft. tall allow a large volume of space for storage and can be very affordable, compared to the cost of multiple base cabinets. Mobile write-up stations can be moved into the lab whenever sit-down space is required for data collection.

Casework truly works like a kit of parts with the ability to add or subtract casework easily by the research team. Notice that none of the casework is on wheels to reduce cost and vibration concerns. Only carts are typically built with wheels.

Mobile carts make excellent equipment storage units. Often used in research labs as computer workstations, mobile carts allow computer hardware to be stacked and then moved to equipment stations as needed. Data ports are also located adjacent to electrical outlets along the casework. Instrument cart assemblies are designed to allow for the sharing of instruments between labs. Carts are typically designed to fit through a 3 ft. wide doorway and are equipped with levelers and castors. Many mobile carts are load tested to support 2,000 lbs. and can be designed with 1 in. vertical slots to support adjustable shelving. The depth of the shelving can vary to allow efficient stacking of equipment and supplies.

Mobile base cabinets are constructed with a number of drawer and door configurations and are equipped with an anti-tipping counterweight. The drawer units can be equipped with locks. The typical height of mobile cabinets is 29 in., which allows them to be located below most sit-down benches. Also, mobile tables are now available for robotic analyzers and designed to support 800 lbs. A mobile cabinet can also be designed to incorporate a computer cabinet, which can be hooked up to the robotic analyzers. Carts incorporate a pullout shelf for the server and a pullout tray for the keyboard in front of the monitor. Wire management is designed as a part of the cart.

Using the Full Volume of the Lab Space

Many labs today are equipment intensive and require as much bench space as possible. Using the full volume of the lab space to stack equipment and supplies can be very helpful and cost-effective. Mobile carts, as mentioned earlier, can be used to stack computer hardware as well as other lab equipment. Overhead cabinets allow for storage above the bench, making good use of the volume of a space. Flexibility can also be addressed with adjustable shelving instead of cabinets. Adjustable shelving allows the researcher to use the number of shelves required, at the height and spacing necessary. If tall equipment is set on the bench, the shelving can be taken down to allow space for the equipment. The bottom shelf should be 19–20 in. above the benchtop and should stop 18 in. below the ceiling to permit appropriate coverage by the sprinkler system.

These laboratories have high, sloped ceilings which allow natural indirect light in, provide engineering services above the laboratory equipment, and provide enough space to stack the equipment easily and safely.

Overhead Service Carriers

An overhead service carrier is hung from the underside of the structural floor system. The utility services are run above the ceiling, where they are connected to the overhead service carrier. The utility services that are run above the ceiling should have quick connect and disconnect features for easy hookups to the overhead service carriers. Overhead service carriers come in standard widths and accommodate electrical and communication outlets, light fixtures, service fixtures for process piping, and exhaust snorkels.

Wet and Dry Labs

Research facilities typically include both wet labs and dry labs. Wet labs have sinks, piped gases, and usually, fume hoods. Wet labs require chemical-resistant countertops and 100% outside air and are outfitted with some fixed casework. Dry labs are usually computer intensive, with significant requirements for electrical and data wiring. Their casework is mobile; they have adjustable shelving and plastic laminate counters. Recirculated air is sufficient. (Dry lab construction is, in fact, very similar to office construction.) A key difference is the substantial need for cooling in dry labs because of the heat generated by the equipment.

D. Design for the Computer

One important change that has occurred in the design of research facilities is that furniture must be designed with computer use in mind. For example, furniture must accommodate the cabling necessary for PCs or laptop computers. Tables should be modular so that they can be added to or rearranged consistent with the fixed casework and the lab equipment to meet criteria for the space. Ports and outlets should be located to accommodate multiple furniture layouts. Write-up stations should to be at least four ft wide to allow for knee space and hardware under the countertop.

Workstations should be 48 in. wide and 30 in. deep, at a minimum. If a computer will be shared, the workstation should, at a minimum, be 72 in. wide and 30 in. deep. In wet labs, computer keyboards must be placed away from spill areas, ideally in separate write-up areas. Laptop computers should be considered for their compact size, mobility, and ease of storage. Electrical outlets must be accessible for plugging in adapters. And, as was mentioned in an earlier section, designers should consider stacking hardware vertically on mobile carts. Laptops with voice-activated microphones are being developed for use in fume hoods, where use of standard laptops can create safety hazards (or where laptops might be damaged by chemical spills).

Three key developments in computer furniture should be emphasized:

- Specialized equipment enclosures.

- Computer hardware enclosures. Hardware enclosures that are fully ventilated and secure are available. Security for computers in a lab is a management and design issue, and designers should consider mobile cabinets with adjustable shelving that can be locked.

- Monitor arms, server platforms, and keyboard drawer solutions. Monitor arms are capable of holding up to 100 lbs. and can support computer monitors of up to 21 in. Mobile server platforms are designed with adjustable shelving to allow stacking of computer hardware. Keyboard platforms can be adjusted vertically and can be mounted under the work surface.

Virtual Labs

Throughout the research industry today, one constantly hears the phrases "virtual labs" and "virtual reality." Virtual labs will become more common each year. Some of the areas in which virtual reality will play a key role in future research are these:

- Virtual manufacturing

- Three-dimensional calibration for virtual environments

- Assembly path planning using virtual reality techniques

- Virtual assembly design environment

- Knowledge-based systems

- Virtual environments for ergonomic design

- Telerobotics

See also WBDG Productive—Integrate Technological Tools

E. Sustainability

A typical laboratory currently uses five times as much energy and water per square foot as a typical office building. Research laboratories are so energy-demanding for a variety of reasons:

- They contain large numbers of containment and exhaust devices

- They house a great deal of heat-generating equipment

- Scientists require 24-hour access

- Irreplaceable experiments require fail-safe redundant backup systems and uninterrupted power supply (UPS) or emergency power.

In addition, research facilities have intensive ventilation requirements—including "once through" air—and must meet other health and safety codes, which add to energy use. Examining energy and water requirements from a holistic perspective, however, can identify significant opportunities for improving efficiencies while meeting or exceeding health and safety standards. Sustainable design of lab environments should also improve productivity.

Key aspects of sustainable design are as follows:

- Increased energy conservation and efficiency

- Reduction or elimination of harmful substances and waste

- Improvements to the interior and exterior environments, leading to increased productivity

- Efficient use of materials and resources

- Recycling and increased use of products with recycled content

Detailed guidance on designing sustainable laboratories is provided in the WBDG Resource Page on Sustainable Laboratory Design.

F. Science Parks

The partnering of research between the public and private sectors has been the main reason for the development of science parks (research parks).

Four major trends that will impact science and technology parks of the future are:

- Networking relationships with other science parks around the world having similar interests

- Increased use of Internet communication

- Increased focus on corporate incubator facilities

- Increased globalization of trade

Several key issues affect the choice of a science park's location:

- The proximity to research universities (almost 90 percent of research parks are located immediately adjacent to a university)

- The availability of a highly educated workforce

- Quality of life of the nearest city

- Proximity to a major airport

- Types and variety of research-based companies in the area

- The ability to expand at the same site.

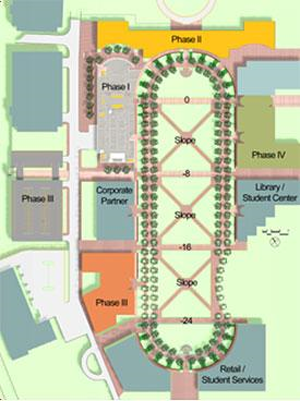

North Carolina State University Centennial Campus: 900,000 sf., College of Engineering

HuaNeng's research campus along the sixth ring in northern Beijing.

Science Parks, Towns, Cities, or Campuses are a major focus for many countries. Above is HuaNeng's new research campus along the sixth ring in northern Beijing. This is one of approximately two dozen companies that will be located in this new science city. There are currently seven science cities in China that are all in construction and will be completed in a few years.

Relevant Codes and Standards

The following agencies and organizations have developed codes and standards affecting the design of research laboratories. Note that the codes and standards are minimum requirements. Architects, engineers, and consultants should consider exceeding the applicable requirements whenever possible.

- ANSI/AIHA/ASSE Z9.5 Laboratory Ventilation

- ANSI/ISEA Z358.1 Emergency Eyewash and Shower Equipment

- Association for Assessment and Accreditation of Laboratory Animal Care (AAALAC) Standards

- Biosafety in Microbiological and Biomedical Laboratories, 5th Edition—Department of Health and Human Services, Centers for Disease Control and Prevention and National Institutes of Health

- Code of Federal Regulations, 29 C.F.R. § 1910.1450 "Occupational Exposure to Hazardous Chemicals in Laboratories" (OSHA)

- PBS-P100 Facilities Standards for the Public Buildings Service—General Services Administration (GSA)

- NIH Design Policy and Guidelines—National Institutes of Health

- Guidelines for the Laboratory Use of Chemical Carcinogens, Pub. No. 81-2385—National Institutes of Health

- NFPA 30 Flammable and Combustible Liquids Code

- NFPA 45 Standard on Fire Protection for Laboratories using Chemical

- Unified Facilities Guide Specifications (UFGS)—Tri-Services, organized by MasterFormat™ divisions, are for use in specifying construction for the military services. Several UFGS exist for safety-related topics.

Additional Resources

Publications

- Building Type Basics for Research Laboratories, 2nd Edition by Daniel Watch. New York, NY: John Wiley & Sons, Inc., 2008.

- CRC Handbook of Laboratory Safety, 5th ed. by A. Keith Furr. Boca Raton, FL: CRC Press, 2000.

- Design and Planning of Research and Clinical Laboratory Facilities by Leonard Mayer. New York, NY: John Wiley & Sons, Inc., 1995.

- Guidelines for Laboratory Design: Health and Safety Considerations, 4th Edition by Louis J. DiBerardinis, et al. New York, NY: John Wiley & Sons, Inc., 2013.

- Guidelines for Planning and Design of Biomedical Research Laboratory Facilities by The American Institute of Architects, Center for Advanced Technology Facilities Design. Washington, DC: The American Institute of Architects, 1999.

- Handbook of Facilities Planning, Vol. 1: Laboratory Facilities by T. Ruys. New York, NY: Van Nostrand Reinhold, 1990.

- Laboratories, A Briefing and Design Guide by Walter Hain. London, UK: E & FN Spon, 1995.

- Laboratory by Earl Walls Associates. May 2000.

- Laboratory Design from the Editors of R&D Magazine.

- Laboratory Design, Construction, and Renovation: Participants, Process, and Product by National Research Council, Committee on Design, Construction, and Renovation of Laboratory Facilities. Washington, DC: National Academy Press, 2000.

Others

- Laboratories for the 21st Century (Labs21)—Sponsored by the U.S. Environmental Protection Agency and the U.S. Department of Energy, Labs21 is a voluntary program dedicated to improving the environmental performance of U.S. laboratories.