by Joseph C. Dean, P.E. and Steve Geusic, P.E., for the Director, Corrosion Policy & Oversight (DCPO), (DASD) [Materiel Readiness]

Updated: 10-14-2021

Introduction

Within This Page

Selection of appropriate paints and coatings are a key design and maintenance strategy for the protection from, and mitigation of, corrosion for facilities, facility components and infrastructure. Many coating system failures result from improper surface preparation and poor application. Coatings and paints represent a sophisticated area of design and specifications and standards application. Generic coating types include:

- Water-borne acrylics

- Alkyds

- Bituminous

- Epoxies

- Coal tar epoxies

- Fluoropolymers

- Inorganic zinc-rich coatings

- Organic zinc-rich coatings

- Lacquers

- Phenolic coatings and phenolic epoxies

- Polyesters/vinyl esters

- Polysiloxane

- Polysulfides modified with novolac epoxy resin

- Polyurethanes

- Moisture curing polyurethanes (MCU)

- Polyurea

- Polyaspartic

- Powder coatings

- Silicones

- Thermal spray metallics

To ensure coating durability and performance for new surfaces or recoating applications, architect-engineers and sustainment professionals should leverage:

- Environmental conditions and severity (Unified Facilities Criteria [UFC] 1-200-01 Department of Defense [DoD] Building Code)

- Corrosion prone locations (UFC 1-200-01 DoD Building Code)

- Service conditions and operational performance requirements (see the Design and Criteria Section of this resource page for more detail)

Typical environmental conditions to be evaluated include atmospheric, soil, ultraviolet (UV) light, biological factors (mold and mildew), stray currents, and internal conditions of pipes and tanks.

For atmospheric corrosion, the appropriate Environmental Severity Classification (ESC) is found in the UFC 1-200-01 DoD Building Code appendices or Corrosion Toolbox.

The next step is to assess and understand related criteria and standards such as Unified Facility Criteria (UFC), Unified Facility Guide Specifications (UFGS), Society for Protective Coatings (SSPC), National Association of Corrosion Engineers (NACE) International (note that SSPC and NACE have merged into a new organization, the Association for Materials Protection and Performance (AMPP)) and tools for paints and coatings selection.

DESCRIPTION

Paint can be defined as a mixture or dispersion of opaque pigments or powders in a liquid or vehicle. Coatings include other materials that can be considered paint-like in their use such as varnishes and inorganic binders. Modern classifications of paints include:

- Architectural/Trade Sales—commonly recognized latex and alkyd paints sold in retail stores

- Industrial/Maintenance—may include anti-corrosive primers, machinery and industrial enamels and other products that require more specialized application equipment. Some trade sales type paints are also used in industrial situations (such as High-Performance Architectural Coatings)

- Specialty—are generally very specific in their use, application and resistance properties such as plastics coatings, coil coatings, and resistive coatings

Figure 1: Common components in a coating

Source: Steve Geusic, P.E.

Paints and coatings serve as the first line of defense between the facility and the environment. Knowing the components and formulations is an essential part of selecting the right paint or coating (see Figure 1). Organic coatings have three basic components: the solvent, the resin (binder), and the pigment. A fourth component, additives, may be present to modify or improve specific properties related to processing, appearance or performance. Not all coatings contain all four components. There are clear, pigment-free coatings and solvent-free coatings, but never binder-free coatings:

-

Binders are also known as the resin, polymer, or vehicle and is the film-forming component of the coating.

-

Pigments include the coloring and filling materials. The insoluble pigment is the heavier, solid portion that tends to settle to the bottom of containers upon prolonged standing.

-

Solvents are the volatile thinners or diluents that evaporate during curing. The remaining binder and pigment are sometimes called the coatings solids. The coatings solids directly affect the thickness of coating films.

Corrosion of metals is an electrochemical reaction that can be controlled by interfering with one or more of the four requirements for a corrosion cell: anode, cathode, electrolyte, and metallic path. Coatings can provide such interference by:

- Providing a barrier to separate the electrolyte from the metal

- Providing chemical inhibitors to control the anodic (corrosion) reaction

- Providing galvanic cathodic protection

The most widely used method to prevent corrosion today, particularly on carbon steel, is the application of high-performance, protective coatings. High-performance coatings are typically used in environments where structures and surfaces require enhanced abrasion and chemical resistance and require added durability. They are described in UFGS-09 96 00 High-Performance Coatings as "special coatings as required for harsh indoor locations or operations (any area subjected to chemical and/or abrasive action), and all outdoor installations", protect a variety of structures in a variety of locations, including: offshore drilling rigs, ships, storage tanks, sewage systems, power plants, shipping containers, pipelines, railway cars and commercial buildings.

Photo 1: Coatings Application with Roller

Source: DCPO

Photo 2: Coatings Application with Spray Gun

Source: DCPO

Annual maintenance and periodic repair costs are far less costly than major repairs or replacement of structures themselves when the appropriate coatings and paints are selected to support the desired life-cycle requirements.

Design and Criteria

As the environmental severity risks increase, so does the stress on the paints and coatings. The incorrect selection of a paint or coating will mean early surface protection failure exposing the surface to corrosion and ultimate component failure. As an example, the coastline is an environment with high salt, moisture, and temperature creating an environment that fosters corrosion at an exceptionally high rate. Because of this, the selection of a paint or coating would dictate a high-performance option versus a conventional exterior latex coating. Understanding surface preparation and correct application methodology is key to a successful coating and painting project.

There are many factors to consider when selecting a protective coating system, including:

- Environmental conditions and severity—UFC 1-200-01 DoD Building Code

- Environmental Severity Classification

- Corrosion-Prone Locations

Note: Protective coating systems can effectively protect steel substrates from corrosion in all environments where corrosion rates are less than 50 mils per year. Where higher rates occur, corrosion-resistant materials may be a better choice.

- Service conditions and operational performance requirements

- Marine and submersion service

- Mechanical abrasion and physical damage

- Water, fuel, solvent, or chemical resistance

- Light reflectivity and heat absorption

- Mold and mildew resistance

- Appearance and aesthetics

- Safety and environmental requirements

-

Substrate properties and condition—For recoating applications, evaluating existing corrosion and surface conditions is critical to determine the appropriate coating and surface preparation prior to application

- Application difficulties and maintenance requirements

- Work-piece access and configuration

- Specialty equipment (sprayers and scaffolding)

- Pot life, dry time and curing

- Out-of-service requirements

UFC 3-190-06 Protective Coatings and Paints requires designers to:

-

Provide paints and coatings that are durable and minimize the need for preventative and corrective maintenance over the expected service life of the component or system.

- Identify the appropriate coating to be used based on UFC, Unified Facilities Guide Specifications (UFGS) and Master Painter Institute (MPI) requirements.

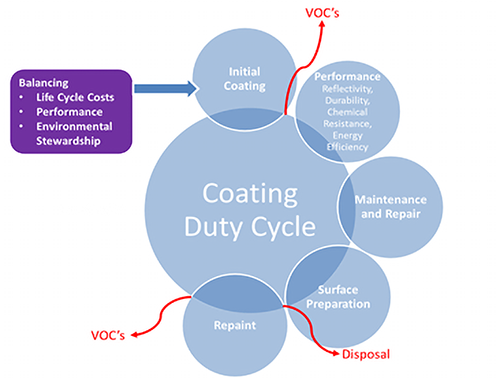

When choosing a coating, designers must balance environmental stewardship, durability and economics. This requires choosing a paint system to minimize environmental impact while maximizing the life cycle. The economics over the entire life cycle rather than just the initial coating must be evaluated. Additional considerations include green building and certification systems, green paint, and energy efficient coatings (see Figure 2).

High-performance paints can be more economical than conventional paints because they require less frequent repaints. The true environmental impact of paint is measured by the total volatile organic compounds (VOCs) emitted over the complete life cycle of the paint. The product with the lowest VOC level might not be the most environmentally friendly choice; for example, products with lower VOCs might have more toxic chemicals or carcinogens. The true environmental impact of paint is measured by the total VOCs emitted over the complete duty cycle of the paint including the environmental hazards associated with effects of surface preparation and disposal during repainting operations. High Performance paints can be more economical and environmentally friendly than conventional paints because they require less frequent repaints and prevent a higher level of durability and corrosion prevention. In high-traffic areas, such as interior doors and frames, a solvent-based coating may be truly the best choice for both performance and environment.

Figure 2: Coating Duty Cycle

Source: Steve Geusic, P.E.

The Master Painter Institute Architectural Painting Specification Decision Tree makes it easier to specify paint systems for the multiple architectural substrates (both interior and exterior). It relies on a simple question-and-answer method to attain the best possible system for a specific substrate and results in the best possible choices in 80% of normal architectural specifications; the remainder or 20% are special-purpose choices that would not be considered under normal circumstances (e.g., epoxy coatings on interior composite wood doors). For more information, review the CPC Coatings Courses in the Continuing Education Section.

Criteria Summary

The UFC 1-200-01 DoD Building Code, Chapter on Corrosion Prevention and Control, provides very specific guidance for design, construction and sustainment actions related to CPC. The Appendix, ESC for DoD Locations, identifies the ESC Zone for each of the DoD Installations around the world, which then drives the selection of the types of materials and processes that should be used for corrosion-prone locations.

The CPC highlights from several of the most relevant UFC and UFGS Paints and Coatings criteria include:

-

UFC 1-300-02 Unified Facilities Guide Specifications (UFGS) Format Standard Defines standards for the use of UFGS. Requires when the selection of a material, component, or system for corrosion prevention, life cycle cost effectiveness, or durability depends on the location, application, conditions, or atmospheric and chemical environment. In the notes, provide direction on identifying and selecting those variables. Use International Organization for Standardization (ISO) 9223 and Environmental Severity Classification (ESC) factors, to help specify when to use materials, coatings, and other design elements in a given project location or atmospheric environment. Additionally, provide direction on what item to use based on other relative criteria such as soil corrosivity, ultraviolet exposure, solar radiation, biological, or other factors causing deterioration of a material or its properties because of a reaction of that material with its chemical environment.

-

UFC 3-190-06 Protective Coatings and Paints provides requirements and technical guidance for the effective use of paint-type coatings to protect common materials such as metal, concrete, pavements, gypsum board and wooden structures at military activities from deterioration. This UFC applies to all Navy, Air Force, and Army service elements and contractors. Requires paints and coatings that are durable and minimize the need for preventative and corrective maintenance over the expected service life of the component or system. Note that this is a significant update from previous versions. Different materials will be used based on local environmental conditions (See UFC 1-200-01 as required in the UFC). Corrosive environments, which require additional corrosion protection, are those project locations which have an Environmental Severity Classification (ESC) of C3, C4 or C5. Humid locations are those in ASHRAE climate zones 0A, 1A, 2A, 3A, 3C, 4C, and 5C (as identified in ASHRAE 90.1). Defines coating systems for specific uses.

-

UFGS-09 90 00 Paints and Coatings addresses "requirements for painting of new and existing, interior and exterior substrates." Discusses corrosion and invokes UFC 1-200-01. Delineates ESC requirements for ESC Zones C3, C4 and C5 and ASHRAE 90.1 humid locations in climate zones) A, 1A, 2A, 3A, 4C and 5C. It includes contractor qualification requirements (SSPC QP 1, QP 2, etc.) and refers to SSPC, NACE, and MPI Standards. Topics include coatings, corrosion, rust, deterioration, mold, and mildew.

-

UFGS-09 96 00 High-Performance Coatings provides guidance on "special coatings […] required for harsh indoor locations or operations (any area subjected to chemical and/or abrasive action), and all outdoor installations." Requires the use of epoxy resin coatings where surface coatings require high corrosion resistance, chemical resistance, bond strength, UV resistance and toughness. It requires compliance with MPI Standards in the MPI Approved Products List and the MPI Architectural Painting Specification Manual prior to the start of any project. A skilled applicator requirement for coating application is included. Degradation, coatings, corrosion, rust, and ultraviolet topics are addressed.

-

UFGS-09 96 59 High-Build Glaze Coatings delineates the requirements for epoxy-polyamide, polyurethane, and epoxy polyester high performance, architectural wall coating systems for interior and exterior surfaces. Addresses surface preparation to prevent corrosion.

-

UFGS-09 97 02 Painting, Hydraulic Structures contains extensive references to corrosion and describes the requirements for the preparation of surfaces and the application of paints for hydraulic structures and appurtenant items. It addresses contractor qualifications and certifications (SSPC QP 1, QP 2, QP 3). While it does not directly address ESC requirements, it does invoke UFC 1-300-02 which does.

-

UFGS-09 97 10.00 10 Metallic Coatings for Hydraulic Structures covers the requirements for preparation of surfaces and application of metallized coatings for hydraulic structures. It addresses contractor qualifications and experience (NACE Basic, Coating Inspector Training and Certification Program, etc.). While it does not directly address ESC requirements, it does invoke UFC 1-300-02 which does.

-

UFGS-09 97 13.15 Low VOC Polysulfide Interior Coating of Welded Steel Petroleum Fuel Tanks describes "the requirements for a Low VOC (< 50 grams/liter) two-coat polysulfide modified novolac epoxy [PMNE] coating [system] for interiors of newly constructed, Navy bulk fuel storage tanks." Notes in the UFGS discuss maintenance coating design. Contractor qualifications and experience (SSPC QP 5, MPCAC-C14) are delineated. Discusses corrosion limitations. While it does not directly address ESC requirements, it does invoke UFC 1-300-02 which does.

-

UFGS-09 97 13.16 Interior Coating of Welded Steel Water Tanks "covers the requirements for polyamide epoxy coating system[s] for interior of newly constructed Navy and Air Force water tanks, potable and non-potable, where shop applied coatings are not being considered." It addresses contractor qualifications and experience (SSPC QP 5, SSPC C-7). While it does not directly address ESC requirements, it does invoke UFC 1-300-02 which does. Designers are encouraged to contact the AFCEC Corrosion Engineer and NAVFAC Atlantic with questions and clarification of the UFGS guidance.

-

UFGS-09 97 13.17 Three Coat Epoxy Interior Coating of Welded Steel Petroleum Fuel Tanks describes requirements when using three-coat epoxy systems for interior coatings of newly constructed Air Force bulk fuel storage tanks. It addresses contractor qualifications and experience (SSPC QP 5, SSPC QP 1 and SSPC QS-1). While it does not directly address ESC requirements, it does invoke UFC 1-300-02 which does. Designers are encouraged to contact the AFCEC Corrosion Engineer and NAVFAC Atlantic with questions and clarification of the UFGS guidance.

-

UFGS-09 97 13.25 Maintenance, Repair, and Coating of Tall Antenna Towers "covers the requirements for coating of new, and repairs to existing, steel towers." It addresses contractor qualifications and experience (SSPC QP 2). Requires a NACE qualified Corrosion Engineer. Discusses corrosion and invokes UFC 1-300-02.

-

UFGS-09 97 13.26 Coating of Steel Waterfront Structures, Zero VOC, (SZC) Splash Zone Coating describes "requirements for using coating new or existing steel-sheet piling and other steel waterfront structures. This coating system may also be used for repairing and coating of aged surfaces." This section lists qualifications and submissions requirements for contractors (SSPC QP 5, C 7, MPCAC). Brief mention of corrosion. While it does not directly address ESC requirements, it does invoke UFC 1-300-02 which does.

-

UFGS-09 97 13.27 High Performance Coating for Steel Structures "covers the requirements for using zinc-rich epoxy/epoxy/polyurethane coating systems for exteriors of new Navy and Air Force steel structures, such as fuel tanks, water tanks, [and] aboveground piping." Extensive notes at the beginning of the UFGS describe special requirements and recommendations. Contractor qualifications and certifications include SSPC PCS and SSPC QP 5. Invokes UFC 1-300-02. Designers are encouraged to contact the AFCEC Corrosion Engineer and NAVFAC Atlantic with questions and clarification of the UFGS guidance.

-

UFGS-09 97 13.28 Protection of Buried Steel Piping and Steel Bulkhead Tie Rods "covers the requirements and application methods for tape wrapping systems that establish exterior protection of buried steel piping and steel bulkhead tie rods that rest above the reference level, 600 mm [2 feet] below Mean Low Water [MLW] or Mean Lower Low Water [MLLW], and for tape coating of buried steel pipe covered with an adhesive thermoplastic resin coating system, a thermosetting epoxy coating system, or a polyethylene-butyl adhesive system" (p. 3). The UFGS states, inspection shall be performed by a [NACE-]certified inspector. Corrosion is mentioned. Invokes UFC 1-300-02.

-

UFGS-09 97 13.00 40 Steel Coatings provides guidance on "the requirements for coating systems, materials, surface preparation, and application of protective coatings on carbon steel." Invokes UFC 1-300-02.

Construction, Quality Control and Sustainment

In order to realize a successful paints-and-coatings project, a critical determining factor is in the selection of the appropriate ESC Zone (see UFC 1-200-01). If the project is included as a construction contract, formal quality control is normally included. If the work is being accomplished as part of a base sustainment project, either as a contract or with in-house personnel, the requirements are the same:

-

If coating selection and developing the coating or recoating requirements are part of the construction (Design-Build) or maintenance activities, then follow the guidance presented in the design and criteria section above

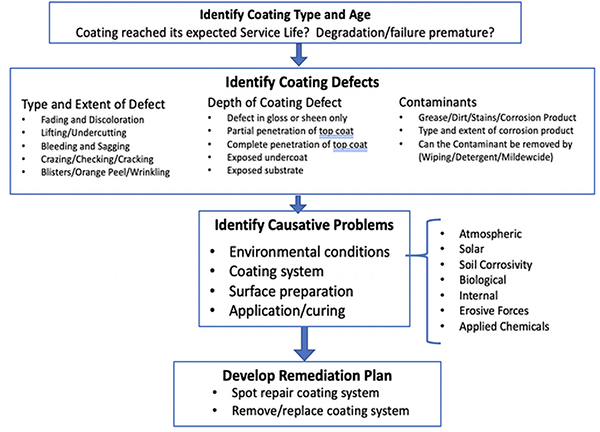

- Assess and quantify the requirement (See figure 3 below):

- Identify coating type and age

- Identify coating defects and extent of work

- Identify causative problems (Consult with subject matter experts if needed)

- Develop remediation plan

-

Verify that the work is being performed according to contract requirements, plans and specifications

-

Ensure quality control through key inspection hold points

Most premature coating failures are associated with deficiencies in one or more of the following:

- Materials

- Surface preparation

- Application

- Curing

- Structural design and substrate properties

- Chemical, physical, and/or mechanical damage to the coating system

Ensuring that premature coating failures do not occur is the challenge that constructors, quality-assurance/quality-control representatives and sustainers face. Figure 3 provides a graphic of the process and challenges of getting paints and coatings right.

Figure 3: Coating Degradation Process Evaluation

Source: Steve Geusic, P.E.

The application of paints and coatings has at its core the following:

- Surface preparation

- Treating of surface irregularities such as holes, weld spatter, sharp edges, and corners

- Cleaning and removing surface contaminants to the desired level

- Producing a surface profile or texture for good adhesion of coatings

Surface contaminants, if not clean or removed, can severely reduce the service life of a coating. Typical contaminants include:

Photo 3: Surface Failure and Flaking

Source: DCPO

- Water

- Dirt and dust

- Paint chalk

- Grease and oil

- Mold and mildew

- Soluble salts

- Loose, cracked, or peeling paint

- Rust

- Mill scale

- Marine biofouling from an accumulation of microorganisms, plants, algae, or animals

Considerations for choosing a method for cleaning and removal of surface contaminants include:

- The type, amount, and adherence of the contaminant

- The service environment

- Any difficulties accessing areas for surface preparation and recoating applications

- The type of coating system selected and its required service life

Methods for cleaning and removal of surface contaminants include:

- Solvent cleaning

- Chemical stripping

- Hand tool cleaning and power-tool cleaning for removing loose rust, mill scale and paint

- Low- and high-pressure water jetting

- Abrasive blasting

- Wet abrasive blasting, which is a mixture of abrasives and water

Specialty removal methods are available such as sponge blasting, which offers excellent dust suppression, and cryogenic blast cleaning used in applications such as mold remediation and equipment cleaning. Surface-preparation standards are available from SSPC and NACE. Many of these standards provide for removal of surface contaminants the required surface profile. Surface preparation standards specify the allowable percentage of surface area for loosely adhering material, tightly adhering material, stains, streaks and shadows.

The standards noted as wet abrasive blast (WAB) cleaning are versions of the original standards and were approved in August 2015. They are titled and numbered the same as dry abrasive blast cleaning, but with a WAB suffix. The WAB standards define five degrees of cleaning that are created using a mixture of abrasive and water. The mixture is created in one of three ways:

- Water is injected into the dry abrasive blast stream

- Abrasive is injected into a pressurized water stream

- Abrasive/water slurry is propelled through the blast hose

Assessing the surface cleanliness before and after cleaning is a critical quality control activity for any painting/coating project. SSPC and NACE provide photo-intensive visual guides to help establish the initial condition of the steel, and the condition of the steel after cleaning by the various dry and wet mechanical methods. These visual guides work in tandem with the various surface cleaning standards used in the project specifications and help determine compliance. The guides include:

- SSPC VIS 1 - Abrasive Blasting

- SSPC VIS 3 - Hand and Power Tool Cleaning

- SSPC VIS 4/NACE VIS 7 - Water Jetting

- SSPC VIS 5/NACE VIS 9 - Wet Abrasive Blasting (WAB)

The basic choices of methods for applying coatings are brush, roller, and spray. There are some specialty tools - such as paint pads, faux finish tools, stippling sponges, etc.

Applicators are often given choices of application methods and must decide the best method for a particular job. Factors that should be accounted for when choosing an application method include:

- Appropriateness for the coating type

- Structural component size, configuration, and irregularities

- Desired appearance

- Access to the workpiece

- Speed, ease, and economics of application method, including the coverage rates and transfer efficiency

- Simplicity of equipment and applicator skills

- Safety

- Environmental requirements

- Weather

Paint-transfer efficiency is the percent of the paint in a container successfully transferred to the surface being coated.

The film thickness of a coating is extremely important. Too thin a film may provide inadequate protection, and too thick a film may reduce flexibility significantly, cause wrinkling or incomplete curing, or otherwise produce adverse effects. The manufacturer's recommendations for coating thickness must always be followed. Should there be a discrepancy between the manufacturer's recommended thickness and that required by the specification, the matter should be resolved in writing before coating operations are started. Before beginning a painting operation, a small patch of the paint should be applied to establish that a continuous film is being properly applied at the specified dry film thickness. Dry film thickness (DFT) is the depth of a cured film usually expressed in mils (0.001 inch) or micrometers.

Wet film thickness (WFT) is the thickness of a wet liquid coating film immediately after application and before evaporation of any volatile material from the film. The applicable standard is ASTM D4414 Standard Practice for Measurement of Wet Film Thickness by Notch Gage. This standard describes the use of thin rigid metal notched gages, also called step or comb gages, in the measurement of wet film thickness of organic coatings, such as paint, varnish, and lacquer.

The following standards apply:

-

SSPC-PA 2 describes a procedure for determining shop or conformance to a specified coating dry film thickness (DFT) range on ferrous and non-ferrous metal substrates using nondestructive coating thickness gages (magnetic and electronic) described in ASTM D 7091. The standard also contains a procedure to determine if dry coatings conform to specified requirements for minimum and maximum dry film thickness.

-

ASTM D7091 describes the use of magnetic and eddy current gages for dry film thickness measurement and is intended to supplement the manufacturers' instructions for the manual operation of the gages and is not intended to replace them. It includes definitions of key terms, reference documents, the significance and use of the practice, the advantages and limitations of coating thickness gages, and a description of test specimens. It describes the methods and recommended frequency for verifying the accuracy of gages and for adjusting (optimizing) the equipment and lists the reporting recommendations.

The SSPC-PA series provide standards for paint application. SSPC-PA 1 is the standard on shop, field, and maintenance painting of steel. This comprehensive specification for shop, field, and maintenance painting is intended to be used for steel which, because of its exposure condition, will be subjected to corrosive attack, either from the weather or from the service environment, and where a high quality of cleaning and painting is essential. The requirements of this specification may not necessarily apply to cleaning and painting steel that will not be subjected to corrosive attack. The following is a list of the major sections of this specification:

- Pre-Application Procedures

- Materials Handling and Use

- Surface Preparation

- Pretreatments

- Coating Materials Preparation

- Factors Affecting the Application of Coatings

- Application Methods

- Shop Coating

- Field Coating

- Repair of Damaged Intact Coatings

- Application Procedures for Generic Groups of Coatings

- Curing and Handling of Coatings

- Inspection

- Safety and Environmental Concerns

Materials, surface preparation, coating application, and the final product are inspected to accomplish coating quality control. These specific inspection items are typically referred to as "hold points." Hold-point inspections can involve visual observations or tests, and the results must be documented. Common inspection hold points and their respective standards are:

- Pre-cleaning

- Surface preparation

- Profile compliance

- Environmental conditions for application and curing such as air temperature, surface temperature, and humidity

- Primer, intermediate and top-coat application

- Wet film thickness

- Dry film thickness

- Degree of cure, tested via solvent rub test, organic coatings

- Post-cure film integrity, tested via holiday detection

It is highly recommended that quality-control and inspection personnel receive appropriate training to ensure that the appropriate checks and balances required during construction and sustainment projects are achieved.

Summary

To ensure that successful paints and coatings projects for facilities are realized, the following actions are recommended:

- Addressing coatings requirements early in the design process

- Understanding the environmental stressors and severities

- Ensuring that all requirements are covered in the project specifications, project order, or shop's work order

- Paint selection and appropriate application methodology explanations, including qualifications, testing, and inspection hold/check points

- Surface preparation requirements

- Application requirements

- Referenced industry standards

- Ensuring that the sustainment program includes periodic inspection, evaluation, and maintenance of coated structures and coating systems

- Employ or contract trained coating inspectors

- Establish a coating-degradation-evaluation process (see Figure 3)

- Leverage the knowledge gained through predictive maintenance

- Utilize sustainment management systems to document condition surveys

- Identify sustainment investment points balancing operational readiness, LCC, service life, and safety

Additional Resources

Department of Defense

Unified Facilities Criteria (UFC)

- UFC 1-200-01 DoD Building Code

- UFC 1-300-02 Unified Facilities Guide Specifications (UFGS) Format Standard

- UFC 3-101-01 Architecture

- UFC 3-190-06 Protective Coatings and Paints

Unified Facilities Guide Specifications (UFGS)

- UFGS-09 90 00 Paints and Coatings

- UFGS-09 96 00 High-Performance Coatings

- UFGS-09 96 59 High-Build Glaze Coatings

- UFGS-09 97 02 Painting: Hydraulic Structures

- UFGS-09 97 10.00 10 Metallic Coatings for Hydraulic Structures

- UFGS-09 97 13.00 40 Steel Coatings

- UFGS-09 97 13.15 Low VOC Polysulfide Interior Coating of Welded Steel Petroleum Fuel Tanks

- UFGS-09 97 13.16 Interior Coating of Welded Steel Water Tanks

- UFGS-09 97 13.17 Three Coat Epoxy Interior Coating of Welded Steel Petroleum Fuel Tanks

- UFGS-09 97 13.25 Maintenance, Repair, and Coating of Tall Antenna Towers

- UFGS-09 97 13.26 Coating of Steel Waterfront Structures, Zero VOC, (SZC) Splash Zone Coating

- UFGS-09 97 13.27 High Performance Coating for Steel Structures

- UFGS-09 97 13.28 Protection of Buried Steel Piping and Steel Bulkhead Tie Rods

- UFGS-09 97 23 Metallic Type Conductive/Spark Resistant Concrete Floor Finish

Tools

Training

- Paints and Coatings Suite of Courses

- Coating Fundamentals

- Coating Selection, Types, Performance, and the Environment

- Surface Preparation, Application of Coatings, and Coating Degradation and Failures

For a complete listing of coatings related training listings, see the Facilities Corrosion Knowledge Track Summary .

DoD Installations Organizations

- Office of the Assistant Secretary of Defense for Construction (ODASD (Con))

- Engineer Research and Development Center, Construction Engineering Research Laboratory (ERDC-CERL) Paint Technology Center

- Air Force Civil Engineer Center (AFCEC)

- Naval Facilities Engineering and Expeditionary Warfare Center (NAVFAC EXWC)